A custom-made french manufacture, without minimum order

OCEA Industries, company located in Vendée, France, is the expert of elliptical and max section tank ends. Thanks to our hydroforming process developed by OCEA’s engineers we master the forming of aluminium, mild steel and stainless steel plates in various dimensions and thicknesses, always with a high quality finished product.

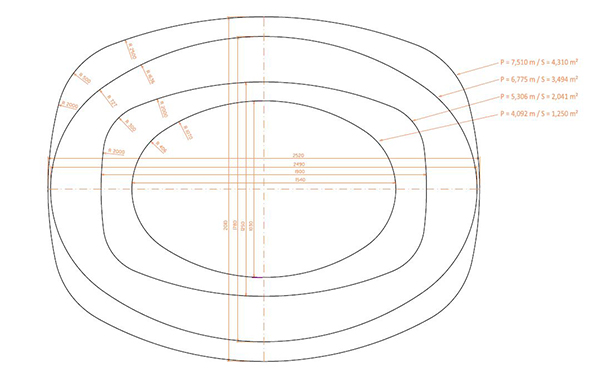

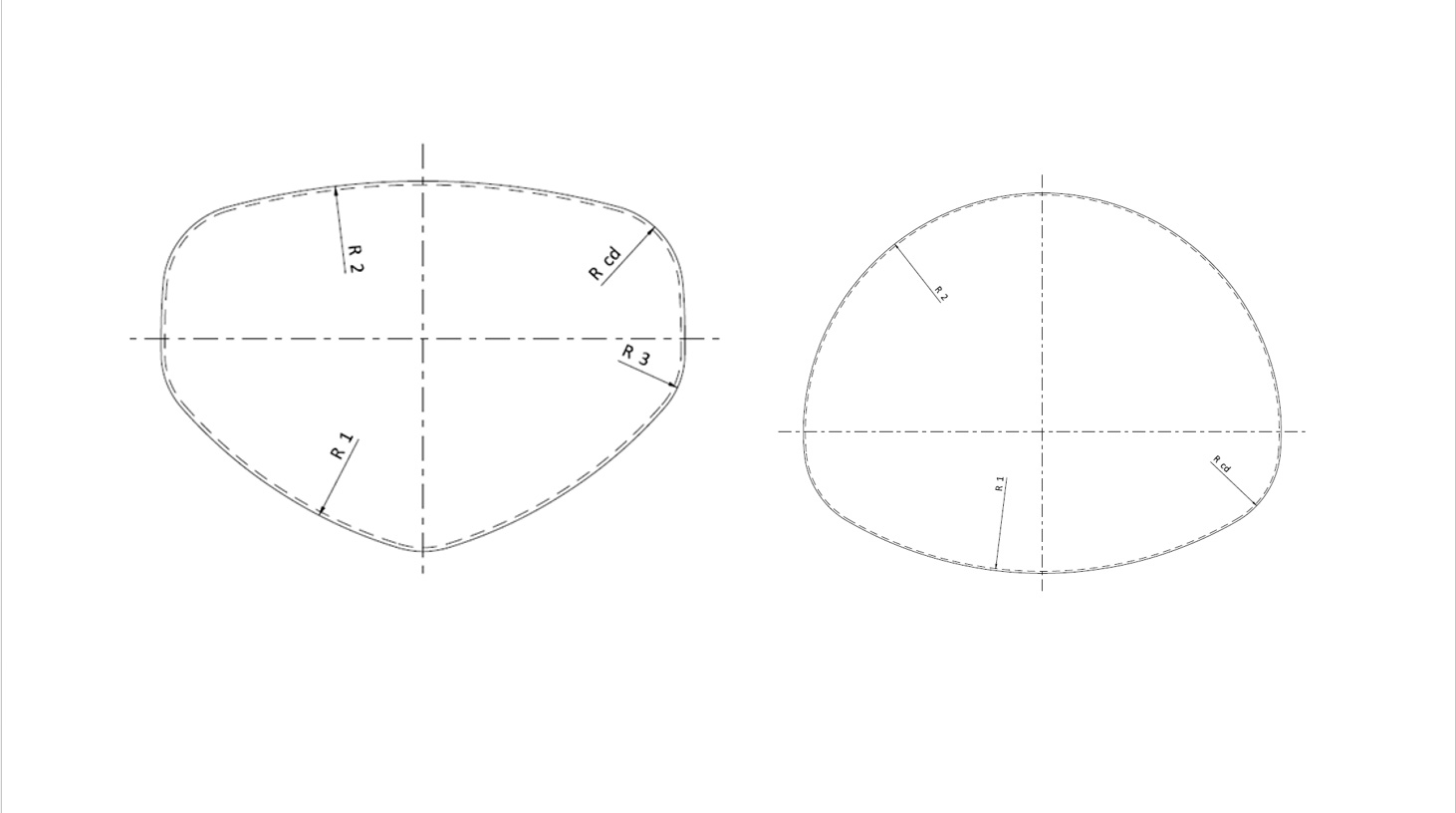

We have more than 400 different templates in our catalogue and because customer satisfaction is our priority, we can give you the chance to create your own design with your exact dimensions.

Furthermore, as all customers are welcome in OCEA, we do not impose any minimum quantity.

Manufacturing process

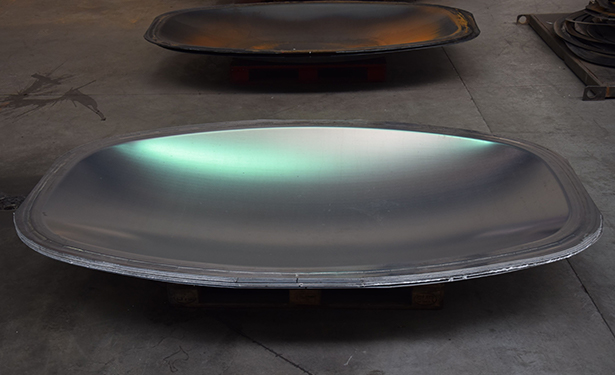

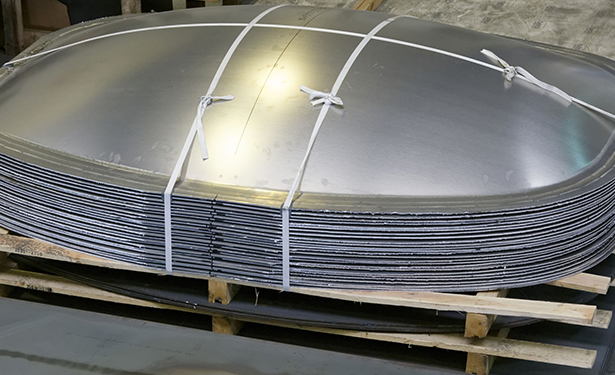

The manufacture of a tank end includes two key steps: the hydroforming and the flanging. Both of these steps are done by our operators trained in our workshop and aware of the finished quality of the product.

Hydroforming

Our engineers developed our own hydroforming process. Hydroforming is a shaping process in which the structure is stressed by the application of hydraulic pressure under a plate. Thanks to this, the material deformation is homogenous. No mould is used and therefore it is the geometry that the structure naturally adopts for a set depth which is preserved.

This process means welding is no longer necessary, and produces a finished product of high quality, in accordance with European standards called “Dish”. The inside and the outside faces stay smooth, without any mark.

Cutting of the dish and flanging

After that, the dish is placed on a flanging machine, composed of 2 heads:

- a cutting head that will cut the dish respecting the shape of the selected template,

- a flanging head that will straighten up the material in order to form the flange of the tank end.

Our production process enables us to change our template very quickly and thus we can propose you very short lead times.